Using centrifugal casting machine

Using centrifugal casting machine The casting when using centrifugal casting machine has two categories, namely, metallic and non-metallic type. Non metal type for sand and shell and the mould shell etc.. Because of the metal type which has a series of advantages in mass production, mass production, so widely used in metal type centrifugal casting machine.

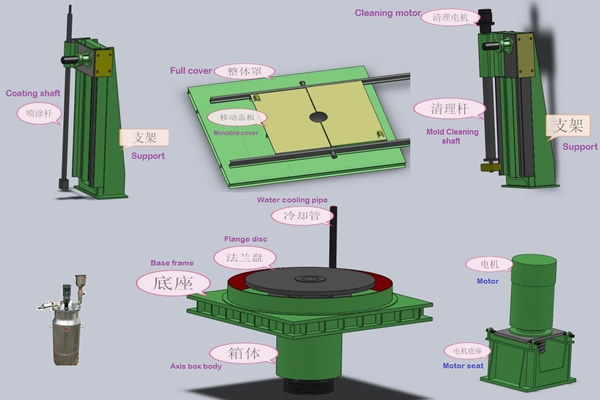

According to the structure characteristics of the main body can be divided into single and double metal type, metal type two horizontal cantilever centrifugal casting machine. The structure characteristics of these two kinds of casting as Fig. 3-1 and 3-2 shows. In the single metal type, type of wall is composed of a layer, single metal type has the advantages of simple structure, convenient operation, but it is damaged to making cast to start production, only single diameter size on casting mold casting.

In double metal type, type wall consists of two layers, casting, surface forming. Double metal type structure is complex, but as long as the work surface size change type centrifugal casting can be of various external diameters. After long time working, only need to replace the relatively simple structure type can use the old cast as a new mold.

/Iron-Pipe-Centrifugal-Casting-Machine/37.html