CENTRIFUGAL CASTING MACHINE HAVING MOLTEN METAL LEVEL DETECTOR

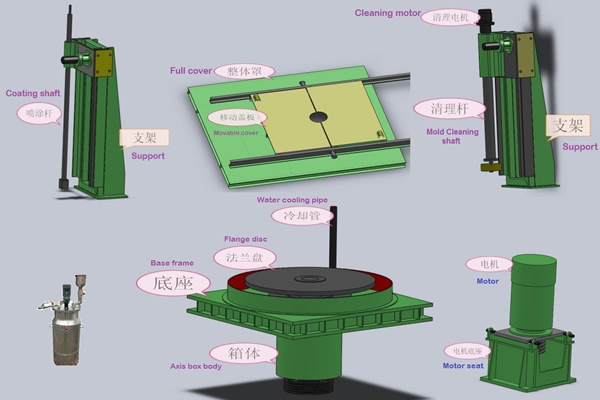

A centrifugal casting machine includes upper and lower rotatable axially movable coaxial clamp members the lower clamp member being engageable and disengageable with a drive motor.

An indexing table conveys successive split centrifugal molds having upper central sprues and conductor members on their underfaces between the clamps. A molten metal reservoir is located above the clamps and has a valved nozzle directed to a hollow shaft of the top clamp which has at its bottom a pair of spaced electrodes. A swingable plate is located next to the table proximate the clamps.

A control network including sensing switches and actuating devices is provided for raising the lower clamp to clamp the mold to the upper clamp, the restricting raising of the upper clamp causing the drive coupling between the motor and the lower clamp and thereafter the opening of the reservoir valve. Upon filling of the mold as sensed by the electrodes the valve is closed, the motor then disengaged and the lower clamp lowered. The sensing elements are shorted by an inverted mold conductor member to prevent valve opening, the absence of a mold as sensed by the excessive raising of the lower clamp terminates the cycle as does the sensing of metal centrifugally flung from the mold.

http://www.centrifugalcastmachine.com/Iron-Pipe-Centrifugal-Casting-Machine/82.html