Turntable Centrifugal Casting Machine

Turntable Centrifugal Casting Machine

The turntable Centrifugal Casting Machines are used to produce the high volume of car, motor, truck and locomotive engine liners, bushes, sleeves, cylinders etc. One set of turntable machine is equipped with 6 to 12 cantilever/shaft spindle heads. Each spindle head rotates from one workstation to the next in clockwise rotation. The turntable centrifugal casting machines adopt fully automated systems utilizing programmable logic controllers (PLC) with functions of automatic pouring, automatic mold coating, automatic mold inner wall cleaning and automatic casting ejection by hydraulic shaft. The casted product’s diameter ranged from 50mm to 500mm with length ranged from 50mm to 500mm.

Key Features of Turntable Centrifugal Casting machine

High volume production

PLC Automatic operation.

Stepless Speed Governing plus frequency conversion motor force driving.

Produce castings with superior metallurgical structure.

Mechanical mold inner wall coating and cleaning.

Automatic casting ejection by hydraulic shaft.

Safety guard of shield cover to prevent the hot metal and cooling water from splashing.

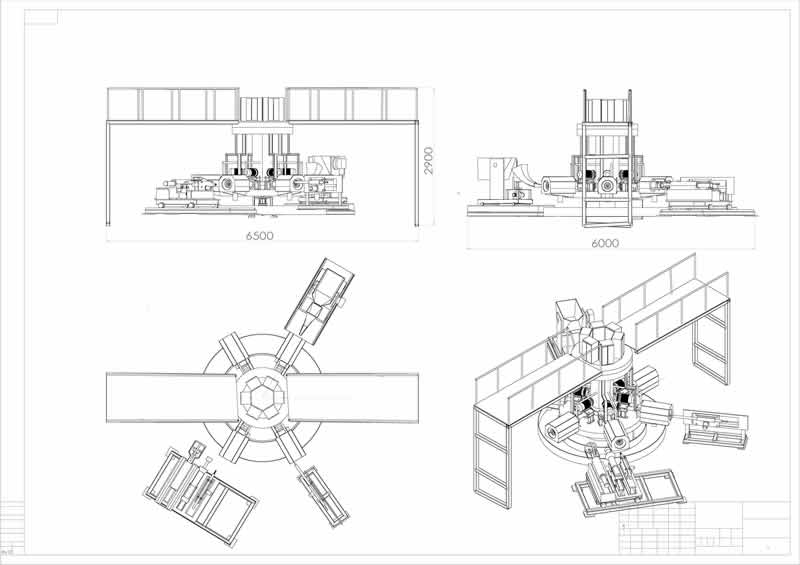

Turntable centrifugal casting machine layout planning

Turntable centrifugal casting machine diagrammatic sketch